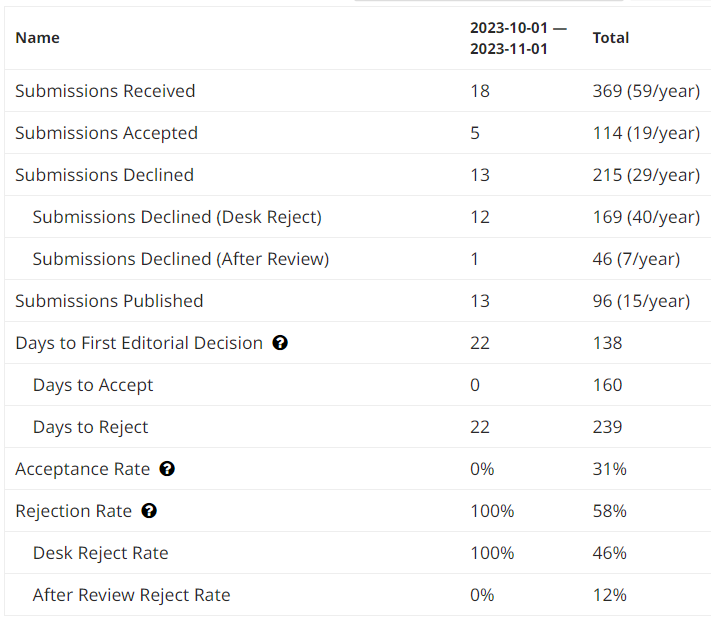

Effect of Addition of Rubber Powder and Eggshell Powder on Clay Soil Parameters in Consolidation and Direct Shear Strength Tests

DOI:

https://doi.org/10.28932/jts.v19i1.5391Keywords:

Rubber Powder, Eggshell, Consolidation, Shear Strength, ClayAbstract

Soil improvement methods can use waste materials to improve the geotechnical properties of the soil. Disposal of waste tires and waste eggshells can cause several problems for the environment. Therefore, one way to deal with it is to recycle used tires as materials for soil improvement. This study aims to determine the effect of the most optimum value on the addition of rubber powder (SK) from waste tires and eggshell powder (SCT) on clay soil parameters. The research was carried out through laboratory tests by testing index properties and engineering properties. Based on the USCS soil classification, the soil sample taken from Hambalang, Citeureup, Bogor, was the organic clay. The percentage of addition of SCT is the same for each variation of mixed soil, namely 3% with the addition of SK which is 9%, 12%, and 17%. The results show that the addition of SK and SCT can increase the internal shear angle from 24,17o in the original soil to 27,82o at 3% SCT+12% SK, increasing the cohesion value from 5,88 kN/m2 to 7,29 kN/m2. The results of the consolidation test showed that at levels of 3% SCT+12% SK, the compression index decreased from 0,19 to 0,12, and the void ratio from 0,85 to 0,55. The results showed that the addition of rubber powder and eggshell powder could improve shrinkage and increase the density of organic clay.Downloads

References

Bowles, J. E. (1996). Foundation Analysis and Design. In Civil Engineering Materials.

Das, B. M. (1995). Mekanika Tanah (Prinsip-prinsip Rekayasa Geoteknik). Penerbit Erlangga, 1–300.

Deepti V. Zutting. (2020). Soil Stabilization by using Scrap Tire Rubber. International Journal of Engineering Research and Technology, V9(06), 1382–1388. https://doi.org/10.17577/ijertv9is060592

Hariyadi, H., Pratama, Y., Sigit, S., Fadhilah, L., Maryunani, W. P., & Sudarno, S. (2018). Pengaruh Ukuran Crumb Rubber Mesh #80 dan Mesh #120 (Serbuk Limbah Ban Karet) pada Penambahan Campuran Laston untuk Perkerasan Jalan. Reviews in Civil Engineering, 2(2), 82–85. https://doi.org/10.31002/rice.v2i2.948

Kaur, M. R., & Singh, E. D. (2019). Tyre Rubber Powder as a Soil Stabilizer. International Research Journal of Engineering and Technology, 6(6), 1786-1791.

Munirwan, R. P., & Jaya, R. P. (2019). Performance of Eggshell Powder Addition to Clay Soil for Stabilization. International Journal of Recent Technology and Engineering, 8(3S3), 532–535. https://doi.org/10.35940/ijrte.c1094.1183s319

Nugraha, A. S., & Manurung, S. A. H. M. (2018). Pengaruh Waktu Pembebanan Uji Konsolidasi 1 Dimensi Terhadap Nilai Oedometric Modulus Tanah Silty Clay. Jurnal Teknik Sipil, 14(2), 161–179. https://doi.org/10.28932/jts.v14i2.1798

Ou, Y., Tian, G., Chen, J., Chen, G., Chen, X., Li, H., Liu, B., Huang, T., Qiang, M., Satyanaga, A., & Zhai, Q. (2022). Feasibility Studies on the Utilization of Recycled Slag in Grouting Material for Tunneling Engineering. Sustainability (Switzerland), 14(17). https://doi.org/10.3390/su141711013

Sadad, I. (2012). Penambahan serbuk karet sir.20 pada tanah lempung sebagai bahan inti bendungan. Jurnal Teknik Sipil UBL, 3(1), 236–246.

Sagidullina, N., Abdialim, S., Kim, J., Satyanaga, A., & Moon, S. W. (2022). Influence of Freeze–Thaw Cycles on Physical and Mechanical Properties of Cement-Treated Silty Sand. Sustainability (Switzerland), 14(12). https://doi.org/10.3390/su14127000

Sandy, J., & Desiani, A. (2020). Parameter Konsolidasi Tanah Organik berdasarkan Uji Laboratorium Akibat Pengaruh Kandungan Batu Bara. Jurnal Teknik Sipil, 16(1), 38–53. https://doi.org/10.28932/jts.v16i1.2768

Venny Riza, F., Sapriandi Lubis, D., Vidia Br Manurung, F., Rizky Rizaldi Nst, M., (2020). Analisis Mekanis Beton Busa dengan Kombinasi Serat Sabut Kelapa Serta Bahan Tambahan Abu Sekam Padi dan Serbuk Cangkang Telur. Progress in Civil Engineering Journal, 2(1), 53–67.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nurfatihah, Sri Wulandari

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.